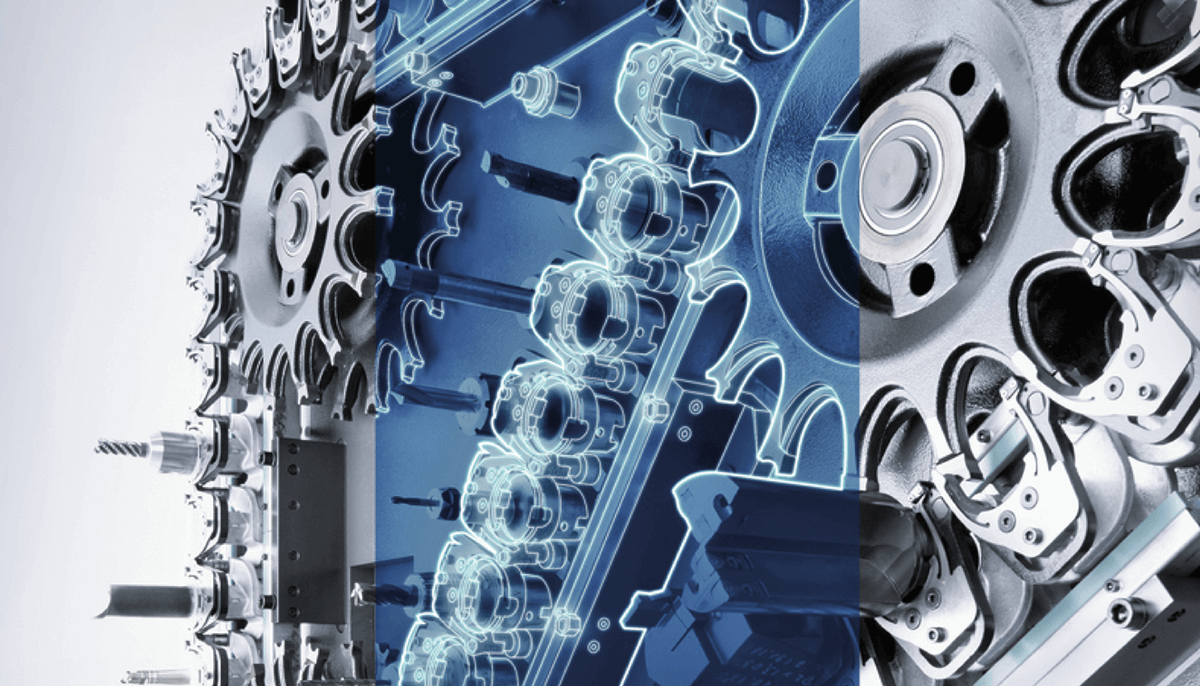

The intersecting angle between the tool and gear axis, and how this affects the revolution speed, also greatly benefits productivity. The process combines hobbing and shaping. Power skiving is a continuous, rotary cutting technique where the tool meshes with the gear being made. This is where power skiving offers a solution. Traditionally, projects that involved machining gears would depend on special machines and processes, which limit the production process – especially in mass production scenarios.

Whether for EVs, robotics or other sectors – like wind power, for instance – manufacturers require more flexibility in their gear machining, an area that, historically, has not been flexible. As we’ve seen with the requirements from smaller, more agile robots, electric engines are also getting smaller and lighter, with a need for tough transmission components to handle the much higher revs per minute that EV engines produce.

The machining challenges we see in robotics are not unlike those we are seeing in electric vehicles (EVs).

In particular, a machining process that has been around for more than 30 years and originated in the automotive sector. The solution lies in taking a better approach to tooling. That’s before we even consider the extra challenges of the continuing Covid-19 pandemic, like unpredictable demand scenarios and the need to maintain productivity with fewer worker on the shop floor. For all areas of manufacturing, cost-cutting remains a priority. This must be achieved cost-effectively with maximized machine uptime, and the highest metal removal rates that relate directly to production speeds. The challenge is on for manufacturers to machine smaller and more precisely engineered-components – like internal gear reducers – with more flexible designs. Not only must these robots be smaller, but also lighter with reduced inertia and able to perform more exact movements with optimal speed and efficiency. Robots factor into a range of industries, from automotive and aerospace to the food industry and pharmaceuticals – yet all of these sectors have common requirements. This was a 12 percent increase from 2018 and a historic high.

The overall number of industrial robots operating in factories worldwide grew to 2.7 million in 2019, according to the 2020 World Robotics Report by the International Federation of Robotics. Here, Harish Maniyoor, global product manager for automotive at the machine tooling specialist Sandvik Coromant explains why power skiving is the answer. This places pressure on manufacturers to machine smaller, tighter components for these machines. Today’s industrial robots must fit into smaller spaces, so as much “manufacturing real estate” as possible is dedicated to production.

0 kommentar(er)

0 kommentar(er)